Whiskey Recipe Basics

Whiskey is made from a variety of different grains including barley, rye, wheat and corn. Different types of whiskies use different types of grains. For example, Bourbon must contain at least 51% corn. Single grain scotch is made with 100% malted barley. Read on for more information on whiskey styles and recipes.

First Things First - Malted Grains

Malted grains are a critical part of every whiskey recipe. In fact, without malt enzymes, it would not be possible to make whiskey with ingredients like corn, barley, or rye. Malted grain is simply grain that has been sprouted. When grain sprouts, the seed creates enzymes capable of converting starch into sugar. Since yeast eat sugar to make alcohol, and grains such as corn and barley are mostly starch, these enzymes play a very important role. They convert grain starch into sugar during the mashing process, making fermentation possible.

Second Things Second - "Basic Whiskey"

Legally speaking (yes, certain legal requirements must be met for all of the spirits we'll list in this article), "whiskey" is defined as follows: Spirits distilled from a fermented mash of grain at less than 95% alcohol by volume (190 proof) having the taste, aroma and characteristics generally attributed to whiskey and bottled at not less than 40% alcohol by volume (80 proof).

The addition of food coloring IS allowed. These characteristics are what define whiskey in general, and the requirements must be met for any spirit to include the word "whiskey" on the label. However, as we'll discuss below, if certain additional requirements are met, other labels may be used.

Bourbon (Kentucky or Otherwise)

The first thing you need to know about Bourbon is that all Bourbon is whiskey but not all whiskey is Bourbon. If we just blew your mind, keep reading, we'll clarify. The second thing you need to know is that Bourbon can be produced anywhere in the U.S. More below.

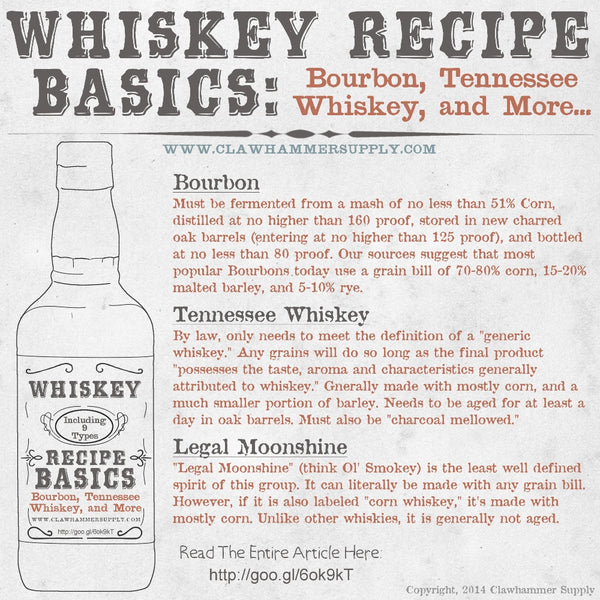

For a whiskey to be labeled "Bourbon," it must be fermented from a mash of not less than 51 percent corn, distilled at no higher than 160 proof, stored in new charred American white oak barrels at no higher than 125 proof, and bottled at no less than 80 proof.

Bourbon has no minimum aging requirement. It can be aged as little as one day and labeled Bourbon, but food coloring may NOT be added. "Straight Bourbon" must be aged for at least 2 years in new charred American white oak barrels.

Bourbon must be distilled in the United states, but regular ol' bourbon does NOT need to be distilled in Kentucky (as many people believe). However, to label something "Kentucky Bourbon," all of the above mentioned requirements must be met and it must be distilled in Kentucky. Sooo, what then is the difference between Kentucky Bourbon and Generic Bourbon? Well, aside from the physical location, it'd be the water. Kentucky prides itself as a state with superior water for distilling, as the earth beneath it is rich in limestone.

For more information on Bourbon, check out this article we wrote on how to make Bourbon.

Tennessee Whiskey

The first thing you need to know about Tennessee Whiskey is that it isn’t Bourbon...or at least it isn't called Bourbon. Folks get this confused from time to time. The second thing you need to know is that, as far a we know it, there is only one small detail that legally differentiates it from regular ol' whiskey (as defined above), which is the process of charcoal mellowing.

During the charcoal mellowing process whiskey is slowly seeped through vats packed with charcoal. The charcoal used for mellowing must be made with the wood of sugar maple trees. To be labeled "Tennessee Whiskey" the spirit must be charcoal mellowed before aging. Some folks say that this removes too much flavor. Other folks say it makes the final product that much better.

For more information, check out our article on how to make whiskey.

Rye Whiskey

Rye whiskey is made from a fermented mash containing not less than 51 percent rye. It must come off of the still at no more than 160 proof and must be stored in charred new oak barrels. However, there is no minimum aging requirement, so one day will do! Food coloring may be (and probably will be) added. Rye whiskey is know for its spicy character and has gained a fair amount of popularity in recent years.

"Straight rye whiskey" must be aged for at least 2 years in new charred oak barrels and food coloring may not be added.

Wheat Whiskey

Wheat whiskey is a style of whiskey mashed with a grain bill primarily consisting of wheat. In fact, the mashing ingredients must be at least 51% wheat. It must come off of a still at no higher than 160 proof, and must be denatured (watered down) to 125 proof or less before aging. It must be aged in charred new oak barrels for at least one day and food coloring may be added.

"Straight wheat whiskey must be aged for at least 2 years in new charred oak barrels and coloring may not be added.

Corn Whiskey

Corn whiskey mash must contain at least 80% corn and it must come off of a still at 160 proof or less. There is no aging requirement whatsoever for corn whiskey. However, if aged, it may be stored in new charred oak containers and must enter the barrel at a proof no higher than 160. It may also be aged in used barrels and must enter the barrel at 125 proof or less. Additionally, manufacturers are not allowed to subject corn whiskey to any manner of "treatment with charred wood." We assume that this means, corn whiskey is not allowed to be filtered or "charcoal mellowed" like Tennessee Whiskey.

Check out our article on how to make corn whiskey for more info.

Malt Whiskey

In the United States malt whiskey must be produced from fermented mash including no less than 51% malted barley and aged in new charred oak barrels. If this whiskey is aged at least two years, contains no additives for taste or color, and has not been mixed with neutral alcohols or other types of whiskey, it can legally be called straight malt whiskey. If a whiskey is not straight malt but contains at least 51% straight malt whiskey, it must be called blended malt whiskey.

Scotch Whisky

There are several types of Scotch Whisky. We'll focus on Single Malt Scotch Whisky here. In a nutshell, there are two things you need to know about this style of alcohol. First, the Scottish spell "whiskey" differently than we do. They omit the "e" and spell it "whisky." If you plan on entering any spelling bee competitions in Scotland, remember this. It will definitely come up. Second, Single Malt Scotch is made with 100% malted barley.

Barley is a common ingredient in most beers and whisky but using 100% malted barley is primarily unique to Scotch. Distillers generally only use 15-20% malted grains in their recipes and the rest is not malted. In most cases, a grain-bill of 20% malt contains enough enzymes to convert the starch in the entire batch of grains into sugar. However, the whisky loving folks in Scotland insist that a grain bill of 100% malted grains produces the best whisky. Additionally, all Scotch whisky must be aged in oak barrels for at least three years. Scotch whisky distilleries often store their product in used Bourbon barrels. See the section below on Bourbon to find out why.

Moonshine

Keep in mind that this article is a review of the legal definitions of spirits made and sold in the United States. In this article, and on our site in general, we refer to moonshine that is legally sold on the shelves of liquor stores. That said, according to TTB rules, there are virtually no rules or regulations on what can be called moonshine, how it needs to be made, whether or not it needs to be aged, whether or not food coloring or artificial flavoring can be added, etc. To learn how commercial distillers make moonshine, check out our post on how to make moonshine.

Leave a comment