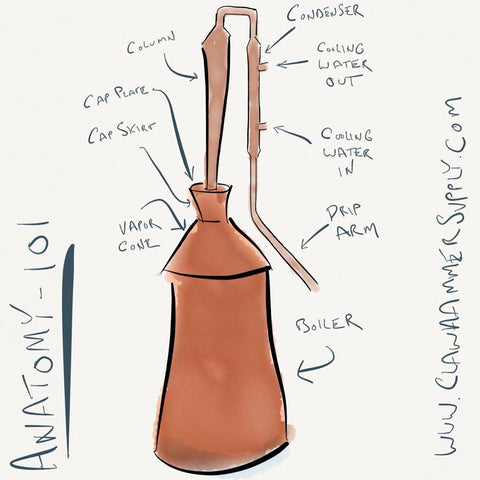

Clawhammer Supply Still Anatomy 101:

Components of a Clawhammer Supply Copper Still

- Boiler: Holds the low alcohol wash, which is heated and distilled into high-proof alcohol.

- Vapor Cone: Directs the alcohol vapor into the column.

- Cap Skirt: Allows the column to slide into the vapor cone. The cap skirt is attached to the bottom of the column. The cap skirt and boiler are joined together with teflon tape. This makes the column removable from the boiler, allowing for filling, emptying, and cleaning.

- Cap Plate: Provides structural support for the column.

- Copper Column: Directs the vapor from the vapor cone into the condenser. The column can be run with a packed column or left unpacked. If the column is not packed, the unit functions like a pot still. If the column is packed, the unit functions more like a reflux still.

- Condenser: Uses cool water to drop the alcohol vapor back into a liquid. The condenser is simply connected to a garden hose that provides the necessary cool water.

- Drip Arm: Directs high-proof alcohol from the still and heat source into the collection jar. The drip arm is a length of copper pipe.

Clawhammer Supply’s still design is known as a hybrid column or fractioning still design. Our design is not a true pot or reflux still.

According to federal rules and regulations, our stills can be used to purify water or make essential oils without any permits. However, states generally require permits for any type of alcohol production and sometimes even for the stills themselves. The information below is predicated on the assumption that the user has procured federal permits as well as the proper permits required by their state and local govnernment.

Reflux stills are very effective at making rubbing alcohol, fuel alcohol, and other types of flavorless alcohol, but can be overkill for making more flavorful products, such as traditional whiskey. They also generally do not include copper parts, and thus, the final product does not benefit from the removal of sulfides, making it less desirable than whiskey distilled with a pot or hybrid still.

Pot stills allow for more flavors to transfer from mash ingredients into the final product. The subtleties of these flavors from a pot still increase the complexity and overall character of the whiskey. Pot stills are less efficient than reflux or hybrid stills, usually creating a lower-proof spirit.

Clawhammer Supply’s design borrows the best features from pot still and reflux column designs. Our design uses a pure copper boiler, an all-copper fractioning column without the reflux coil, and a simple and efficient in-line condenser. These elements allow for greater efficiency than a standard pot still and more flavor retention than reflux stills. Essentially, our stills distill quickly and efficiently without stripping the character from the final product.

Leave a comment