There are several different ways to make watermelon moonshine. I know this because I've experimented with many of them. In fact, a few years ago I walked into a grocery store and saw a bin of the first fresh watermelons of the season. My first thought wasn't about eating them. It was, "I wonder if I can turn these watermelons into moonshine." But why would someone want to turn watermelons into moonshine?

In my experience, alcohol made with fruit is a delightful and unique experience. There are thousands of types of whiskies, vodkas, gins, and more to choose from. But have you ever tasted fruit brandy made from pure watermelon juice? It's one of a kind, I can tell you that for sure. And it's pretty good too.

What is Watermelon Moonshine?

There are three types of watermelon moonshine: watermelon fruit infusions, watermelon moonshine cocktails, and watermelon moonshine brandy. The first two types are made by adding either watermelon chunks or pureed watermelon to high proof alcohol. Watermelon moonshine is made by converting watermelons into alcohol, which is quite a bit more complicated.

How is Watermelon Moonshine Made?

We'll start by explaining how to make the most complicated type of watermelon alcohol: watermelon moonshine brandy. This is a type of alcohol made directly from the juice of watermelons. To make this type of spirit, a licensed distiller would juice the melons, ferment the juice with yeast, then distill in a pot still to make high proof watermelon brandy. But as we mentioned, this isn't the only way to make it. A (much easier) process called maceration can be used to create intensely flavorful watermelon moonshine drink that's even more delicious than watermelon brandy.

Watermelon Moonshine Recipes

In this article I'm going to give you three options for how to make watermelon moonshine, step by step, with pictures. I've organized the by how difficult they are to make. Watermelon fruit infusions and cocktails are fairly easy to make. Watermelon moonshine is much more difficult

- Watermelon Moonshine Fruit Infusion

- Watermelon Moonshine Cocktail

- Watermelon Moonshine

- Other Moonshine Recipes

Watermelon Moonshine Fruit Infusion

This method is fairly easy. Remove the rind from a ripe watermelon and cut the fruit into 2 inch chunks. Add to a 1/2 gallon glass container with a large lid. Top off the container with 151 proof grain alcohol. Refrigerate for 2 weeks. After steeping the fruit, pour through a coffee filter (to remove fruit pulp) into a 750ml bottle or into mason jars. Once you're finished it should look like this:

The Best Watermelon Moonshine Cocktail

On a scale of 1-10, this watermelon moonshine cocktail recipe is a 13. In other words, the flavor is off the charts. I've had this before, but of course I drank the one in the picture below. It was even better than I remembered. Perhaps it was because I was at work when I drank it? Either way, here's our all-time favorite watermelon moonshine cocktail recipe. It requires a bit of prep work and a bullet blender, but the final result is well worth the effort.

Ingredients

12-15 one inch watermelon cubes

1.5 oz 151 moonshine

3 mint leaves

1/2 oz lime juice

1/2 oz simple syrup

Steps

- Remove the rind and cut a fresh watermelon into 1 inch cubes.

- Place on parchment paper and freeze.

- Once frozen, transfer to a 1 gallon freezer bag.

- Place 10 watermelon cubes into a bullet blender,

- Add, 1.5 ounces of 151 alcohol, 3 mint leaves, 1/2 oz. lime juice and 1/2 oz simple syrup.

- Blend lightly (until watermelon cubes have been broken down)

- Add to a mason jar and top off with additional frozen watermelon cubes, which will act as ice cubes.

*Note, Ole Smoky's White Lightning works well for this. I also recommend using additional frozen watermelon chunks as ice cubes. It works perfectly and looks great.

How to Make Watermelon Moonshine

As I mentioned, it's entirely possible to turn raw watermelon juice into (nearly) pure alcohol. The procedure for making watermelon moonshine from scratch is as follows.

Please note that this article is for educational purposes only. When we conducted this experiment we had a federal fuel alcohol permit and were also compliant with state and local requirements. To distill alcohol at home in the United States requires federal, state and local permits. Our distillation equipment is designed for legal uses only and we don't advocate or condone violating the law.

Mashing Equipment

The first step is to make a sugary liquid with watermelon juice. The following items were needed:

-

Cutting board and a sharp knife

-

Blender

-

A fine cheesecloth

-

A couple of 5 gallon buckets

-

Large pot for mashing

-

Hot plate

-

A large paddle or spoon for stirring

-

Wort / immersion chiller (for cooling the mash)

-

A hose for siphoning

-

Thermometer

-

A glass carboy or food grade plastic bucket for fermentation

-

An airlock

Ingredients

-

5 large watermelons

-

2 pound of raisins

-

4 pounds of cane sugar

-

2 packets bread yeast (or wine yeast)

Mashing, Fermentation, and Distillation Procedure

-

First, we extracted the sweet, sweet watermelon juice from 5 large watermelons. We found that the easiest way to do this is to cut the Watermelon in half and then into quarters. Once quartered, we cut into slices and removed the rind. Next, we reduced it to chunks that will fit into a blender.

-

Next, we added chunks to the blender and obliterated the watermelon!

-

We made sure not to over-blend. We shut down the blender as soon as the fruit had been liquefied. This will be filtered through a cheesecloth later and if the blended watermelon is too fine the pulp will go right through the strainer.

-

We dumped our watermelon puree through a cheesecloth installed in a food safe bucket. Nylon paint strainer bags are a good alternative to cheesecloth.

-

We removed the cheesecloth containing pulp from the bucket and let some of the juice drip out.

-

Once the bag was a manageable size, we squeezed it to extract as much watermelon juice as possible.

-

After squeezing, we poured the strained watermelon juice into a large stainless steel mash-tun.

-

Add sugar to the juice and stir until it dissolves.

-

Add 2 pounds of raisins.

-

We heated the strained watermelon juice, raisins, and sugar to 160F. This will kill most of the naturally occurring wild yeast and bacteria found in the watermelon juice.

-

After heating, we added cold water to reach a total volume of 5 gallons (if needed).

-

We cooled the mash to 70 degrees with a sterilized wort-chiller.

-

While the mash is cooling, we made a yeast starter using 2 cups of 120F water, 2 tsp of sugar, and 2 small packages of bread yeast.

-

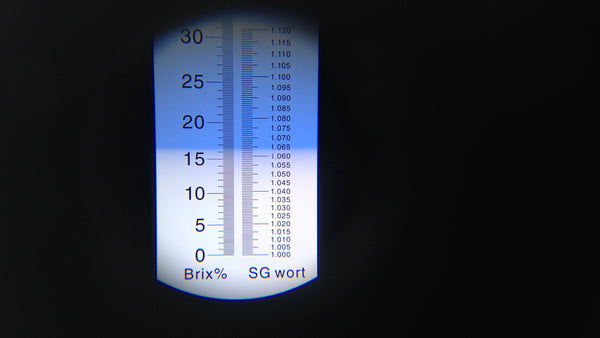

We took a starting gravity reading using a brix refractometer. We loaded the hydrometer by using a small dropper to remove a bit of juice from our mash pot.

-

Ideally, the brix reading should be around 1.065, which will produce a starting alcohol of about 8%. If the reading is low add 100% pure cane sugar until the desired starting gravity has been reached.

-

Here's what a brix refractometer reading looks like

-

We aerated the mash by transferring it between two sterilized food grade buckets. We poured it hard so lots of bubbles form on top of the liquid.

-

Transfer the 70 degree mash to a sterilized fermentation vessel.

-

Add the yeast starter to the fermenter.

-

Admire the beauty of the carboy full of watermelon juice.

-

We added an airlock and fermented at 70F until finished. Read this article on fermentation to learn more about how to tell when fermentation is finished.

-

Our batch finished very quickly (in about 2 days) due to a high starting temp (which is not ideal).

-

Once the bubbles in the airlock slow down/stop take a gravity reading. Once the gravity reading does not change for 3 days or is 1.010 or below it is done. Our gravity finished just below 1.00, giving us a starting alcohol of about 8.5%, which is exactly where we want to be.

-

After letting the wine settle for another 3-4 days (this will give the yeast time to settle to the bottom of the fermenter), we siphoned it into a 100% copper still.

-

We left the raisins, settled watermelon pulp, and as much yeast behind as possible.

-

After that we distilled in a 5 gallon copper still.

Again, it is illegal to distill alcohol without federal and state distillers or fuel alcohol permits.

Additional Notes:

As we've discussed in previous articles on alcohol yield, the final take from a distillation run will be highly dependent on the amount of sugar that is started with in the mash. Much of the sugar in this recipe will come directly from the watermelons. However, we've added some sugar as well.

Why did we add sugar to this recipe? Well, fresh watermelon juice has an average brix of about 10. Some are higher. Some are lower. But that's a good average to use as a rule of thumb.

The particular watermelons we used had a brix of around 8. About 20% lower than the average. We bought them from Walmart and they were grown in Mexico...and we got what we paid for! If we hadn't added sugar, our starting alcohol wouldn't be any more than about 4.5-5%. For the sake of maximizing our efforts we bumped that number up to 8%. This was just an experiment to see if it could be done, so we stopped there. One could add enough sugar to boost starting alcohol to 20% for fuel alcohol.

Leave a comment